Home > Accessories > Drader Injectiweld Accessories

Scraping Blades

Drader’s metal scrapers and etchers can increase the strength of a weld by decreasing stress points. Two designs of Scraping Blades are available to enable an operator in pre- and post-welding procedures.

Air Filter

Injectiweld Air Filter function is essential for clean, dry air and for keeping airborne articles from contaminating the welder. To operate the Injectiweld Air Filter:

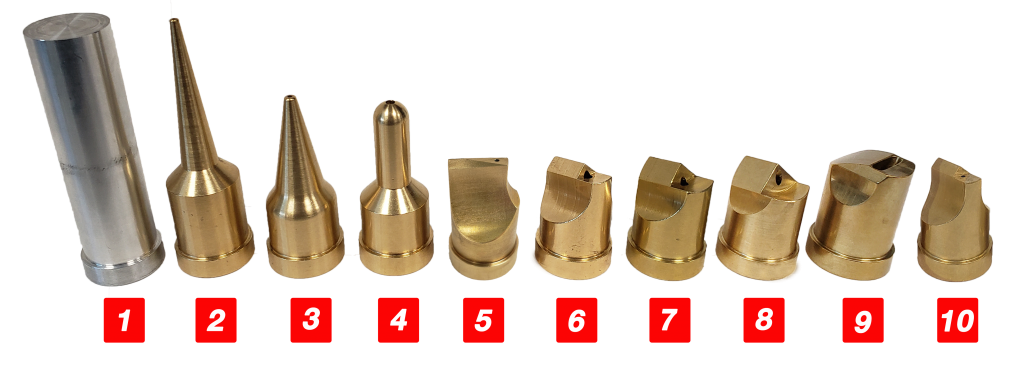

Inter-Changeable Welding Tips

All Drader Injectiweld welding tips are made of brass, with the exception of Blank Tip which is made of aluminum. The type of plastic weld will determine your tip choice. See the description below to select the right tip for your needs.

| # | Description | Item ID | Main Usage |

| 1 | Blank Tip | ITIP-2BL-5.5 | Custom tips; design your own for your special application |

| 2 | Prototyping Tip | ITIP-2PR | Prototyping, repairs, filling holes, spot welding tight areas |

| 3 | Repair Tip | ITIP-2RP | Repairs, filling holes, spot welding tight areas, prototyping |

| 4 | Bull-Nose Tip | ITIP-2BN | Repairs, filling larger holes, filling larger voids |

| 5 | 3/16” Legacy Fillet Weld Tip | ITIP-2F6LEGACY | 90º fillet welds, butt welds, repairs |

| 6 | 1/4” Fillet Weld Tip | ITIP-2F4 | 90º fillet welds, butt welds, repairs |

| 7 | 3/8” Fillet Weld Tip | ITIP-2F8 | 90º fillet welds, butt welds, repairs |

| 8 | 1/2” Fillet Weld Tip | ITIP-2F5 | 90º fillet welds, butt welds, repairs |

| 9 | 5/8” Ribbon Weld Tip | ITIP-2RW | Sealing; re-enforcement; non-pressure welds |

| 10 | 3/16″ Fillet Weld Tip | ITIP-2F6 | 90º fillet welds, butt welds, repairs |

Fillet tips are used mainly for fillet welds [90º] and butt welds. Welders can use the Fillet tip to weld from inside corners out and are able to seal corners without changing tip style. Fillet tips can also be used for crack repairs, as long as the crack is somewhat straight. The longer preheat section allows faster welding speed than welding cracks with the conical tip.

Repair tips are used for crack repairs, filling small holes, spot welding, for reaching tight areas, and for prototyping. Because of their conical shape, they all offer similar types of welds. The Bull-Nose tip is used to repair larger holes. Choose the size that best suits your application.

The Ribbon weld tip is used to make a seam weld on thermoplastic materials, such as belting and thin sheets. Because this welding tip does not weld down to the root side, it should not be used for regular butt welds.

The Injectiweld Air Filter comes with simple instructions for maintenance and replacement. Injectiweld Air Filter function is essential for clean, dry air and for keeping airborne articles from contaminating the welder. To operate the Injectiweld Air Filter:

If your welding operation requires cleaner welds, invest in these low-cost tools. Drader’s metal scrapers and etchers can increase the strength of a weld by decreasing stress points. Two designs of Scraping Blades are available to enable an operator in pre- and post-welding procedures.

Please give our friendly team a call to assist you.